Why We Love Tru-Flat Plywood for Laser Cutting Projects

If you’ve ever worked with plywood, you know it can be hit or miss — warping, chipping, and inconsistent finishes can turn a great design into a frustrating project. That’s why we’re big fans of Tru-Flat Plywood here at Rise LaserWorks.

So what makes Tru-Flat different?

It’s a premium, laser-friendly plywood with a smooth MDF core and a real wood veneer on both sides — pre-finished with a durable UV coating. That means you get a stable, flat material with a clean, professional look straight off the laser.

Here’s Why It Stands Out:

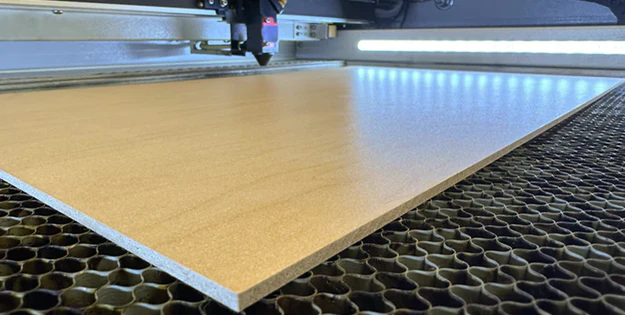

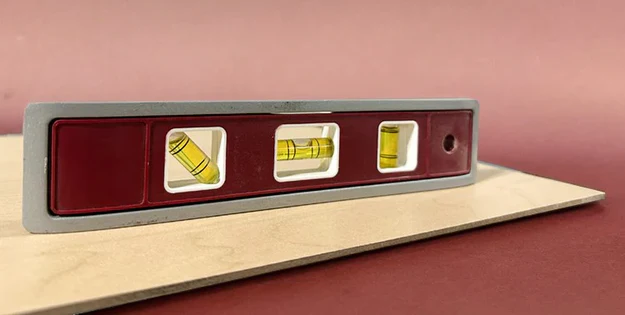

1. Perfectly Flat Sheets

True to its name, Tru-Flat resists warping and stays consistently level — even in thinner sizes. That makes it ideal for laser cutting where precision is key.

2. UV-Coated & Ready to Go

Each sheet comes pre-finished with a UV-cured coating, giving it a rich, even sheen and protecting the surface from scuffs and wear. No need for sanding, sealing, or finishing — it’s ready to use right off the bed.

3. Clean Cuts & Crisp Engraves

Thanks to the consistent MDF core and quality veneer, Tru-Flat cuts clean and engraves with sharp detail. It handles intricate designs with ease and produces a beautiful contrast in engravings.

4. Super-Fast Paint Fills

No more meticulous painting inside the lines. The coated surface allows for a quick fill and wipe – it’s that easy!

5. No Surprises Inside

Tru-Flat has no interior voids like typical plywood, which means fewer errors, blowouts, or wasted material during cutting. What you see is what you get — every time.

6. It’s CANADIAN🍁

No explanation needed… from the True North, Strong and Free.